Technology

Every hour, the Earth receives enough sunlight to meet the world’s energy needs for one year. At Eurotron, we embrace sunlight through developing turnkey automation solutions for PV module manufacturers.

Back-contact

PV modules

We are the global market leader in automation solutions for back-contact PV modules. In this type of module, the electrical interconnection of the cells takes place on the back, as a result of which the metal covering at the front is largely or even entirely absent and the metal patterns are hardly visible, if at all.

Because the electrical connections are all on the back, there is no need to connect the cells at their front side. As a result of that, there are no shading losses and resistive losses are reduced to an absolute minimum. With industrial partners that include manufacturers of materials, equipment, cells and modules, we are working to further optimize this technology and the resulting products which are used in solar farms, rooftop installations, for building integrated PV and vehicle integrated PV.

Compared with most other modules, back-contact PV modules come with following major benefits:

- reduce 3% shaded area with no busbars

- reduction of resistance losses increases power output

- denser spacing of solar cells increases the overall module output

- the absence of a cross connector reduces the module dimensions

- reduction of module temperature increases real life power output

- less hotspots due to the metal which acts as a heatsink

- less micro cracks, resulting in a more reliable module

- higher reliability due to different electrical connection adds to lifetime increase

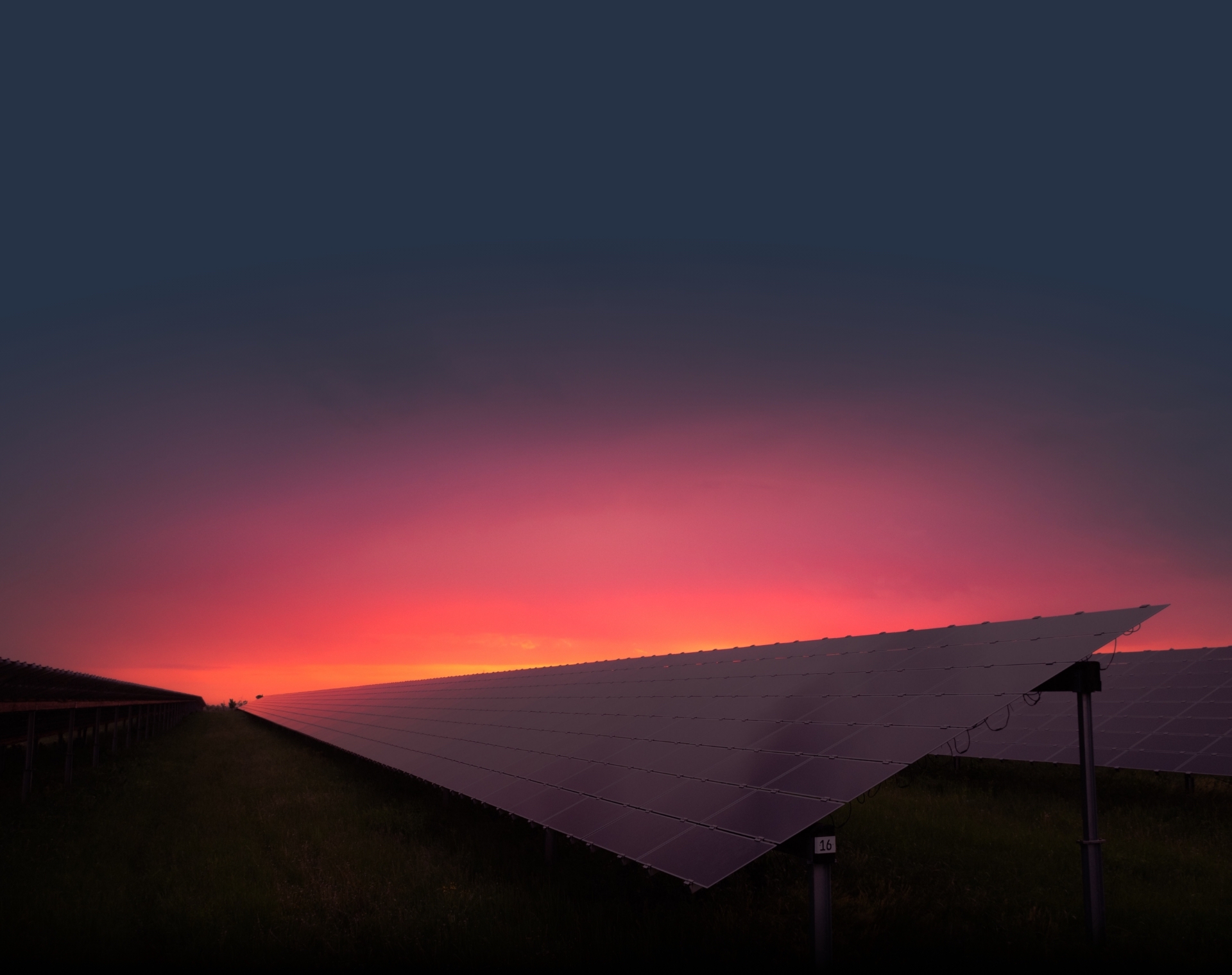

Solar farms

Solar farms are sprouting up in all shapes and sizes, from small ones that light up local communities to gigantic, utility-scale solar farms that power thousands of homes. A large collection of PV modules absorbs energy, convert it into electricity and send that electricity to a power grid for distribution and consumption.

Solar roofs

PV modules on roofs is one of the most common way of generating electricity. It’s a great way to offset energy costs and reduce the environmental impact of homes.

Integrated

solar roofs

Integrated solar panels are designed to sit flush with your roof replacing existing tiles. They appear more streamline and blend in more seamlessly, making integrated solar panels the more attractive option.

EV-mobility

A game changer! What if we use the sun to move ourselves from A to B. We are closely involved in initiatives to integrate solar panels into vehicles and reduce the need for grid-charging. Lightyear 0 redefines mobility. Together we write history with every clean solar kilometer the drive.

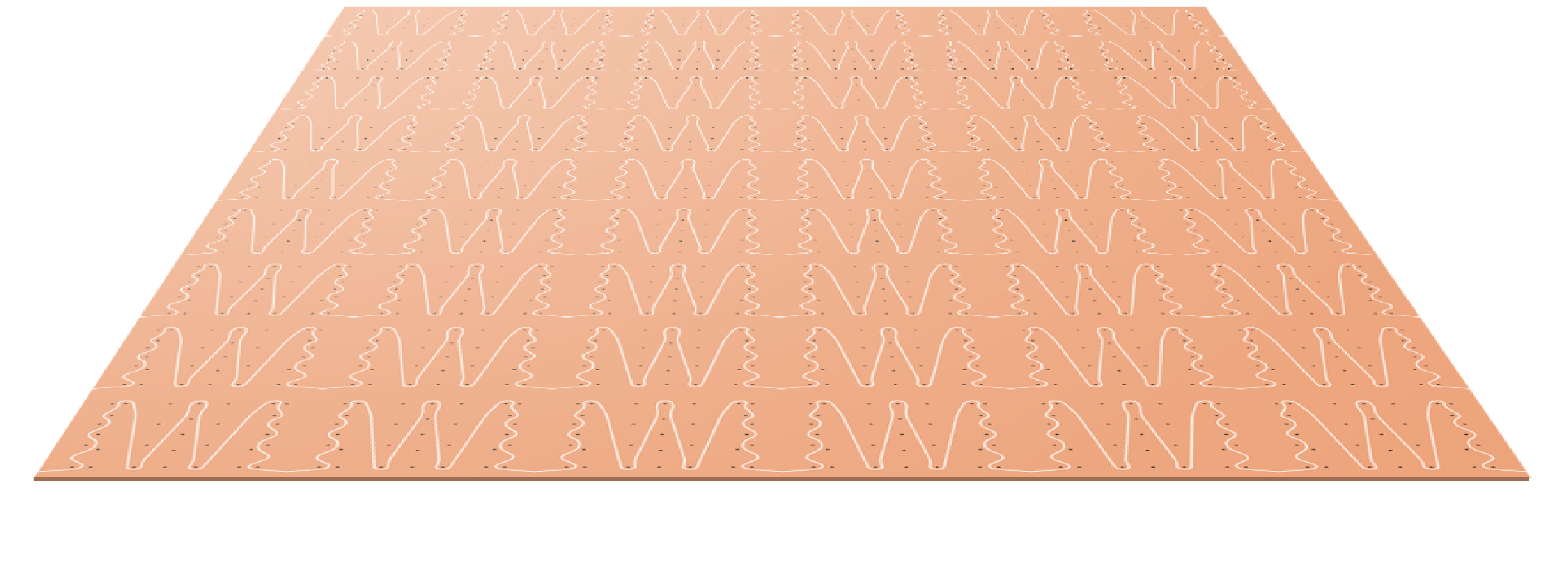

Conductive backsheet technology

Conductive Backsheet (CBS) technology is a cell connection process specially developed for back-contact solar cells, which is characterized by low mechanical stress on the cells. This technology makes it possible to connect even very thin ZEBRA cells to a structured copper foil using conductive adhesive and thus to integrate them monolithically into a module.

Module encapsulation

Replacing conventional soldering with conductive foil and 2D encapsulation structure results in:

Avoiding strain and micro cracks due to the conventional high temperature soldering, single glassed module life cycle increased up to 30 years.

Lower encapsulation loss, increase module efficiency

Lower operating temperature, higher output

Better choice for ultra-thin wafer applications

Aesthetic Design, lead free

Higher module efficiency

One of the primary advantages of back-contact modules is to increase the cell efficiency by minimizing frontside shading losses from the topside cell metallization. By abandoning traditional high temperature soldering processes (>200oC), the stress and microcracks caused by soldering that typically occur on solar cells can be avoided. This increases the reliability and lifetime of back-contact PV modules. Another advantage to back-contact modules is a significant reduction in manufacturing process steps by simplifying the way in which the cells are interconnected.

Production

Time

Strong partnerships

We are committed to change the global solar industry with our groundbreaking technology. However, we can’t do this on our own. To realize this, we established strong partnerships. We cooperate with leading European research institutes, such as TNO, ISC-Konstanz and with technological partners like Endurans Solar and SPP.

Get in touch

Let's connect to discuss the possibilities for your facility.